It is safe to say that Denim is one of the most popular materials in today’s world as most of us have few pairs in our collection. But where did it originated from and how it is made? In this document, I will try to explain most of the common aspects of Denim and this will be the part of a series where we will talk about various fabrics that are most commonly used in today’s world.

What is Denim?

Simply put, Denim is a type of woven twill fabric, usually made from Cotton. It is a sturdy cotton warp-faced textile in which the weft i.e. the yarn that runs across, passes under two or more warp threads and the warp yarn are more prominent on the right side. So, it consists of two yarns that are woven together. This twill weaving produces a diagonal ribbing that distinguishes it from cotton duck, which is a heavy, plain woven cotton fabric. While a denim predecessor known as dungaree has been produced in India for hundreds of years, denim as it is recognized today was first produced in Nimes, France.

Denim is available in range of colors, but the most common is indigo in which the wrap thread is dyed while the weft thread is left white. As a result of the wrap-faced twill weaving, one side of the textile is dominated by the blue wrap threads and the other side is dominated by the white weft threads. Jeans fabricated from this cloth are predominantly white on the outside. However, with the advancement of alternative dyes such as sulfur, the definition of denim can be stretched to include garment-dyed twills as well.

The History

‘Denim’ originated as a contraction of the French phrase serge de Nîmes (serge from Nimes/from Nimes), which is a French denim-like fabric that gained popularity in England in the 1600s. It is believed that it was first invented in Genoa known as ‘bleu de Gênes’ and majority of it was exported to the French town Nîmes. The word ‘jeans’ comes from the word ‘Genes’, which is a French word for the city of Genoa.

The weavers in Nîmes was experimenting with producing their own robust and durable blue cloth and succeeded in developing something called a twill cloth, which was made from wool and raw silk. They made it with pattern of diagonal parallel ribs by using two different threads where the warp yarn was dyed with indigo and the weft yarn was left white.

As stated earlier, the French named their own cloth ‘serge de Nîmes‘, which eventually was turned into the now famous name ‘denim’ by the Americans and English.

First introduced in the United States in the mid-19th Century. It initially became popular in the United States during the Gold Rush in 1853, when Levi Strauss began making durable pants for miners with big pockets for storing gold. Jacob W. Davis, a tailor from Nevada, manufactured the first pair of rivet-reinforced denim pants and as it gained mass popularity, Davies could not cope with the demand and he joined hands with Levis Strauss & Co., and patented the pants and Strauss began mass production and marketing.

For a long time, the blue jeans were seen as ideal for miners and sailors and Levi Strauss, never wore a pair of his own jeans, as he was a wealthy businessman and jeans were supposed to be made for the poorer people. As it turned out, Denim has become a mainstream fashion item from something worn exclusively by working men.

Jacob W. Davis (Left) and Levi Strauss

Types of twill used for Denim

There are different types of twill used for denim, but the most common type of twill is ‘three by one’ which is 3×1 right handed twill and it means that, on the fabrics face (front), there are three warp yarns for every weft yarn. As denim is warp-faced, this is why denim has diagonal lines in the fabric, known as twill lines. ‘Right Hand’ means that the twill runs from right to left on the front side of the fabric.

The there is ‘two by one’ which can be found sometimes and it means that there are two warp yarns for every weft yarn. However, the 3×1 left hand twill where the twill lines run from left to right is used more commpnly.

In addition, something called broken twill was also invented to prevent the fabric from pulling in the direction of the weave, which results in ‘leg twist’.

How is Denim Made?

Cotton denim is woven either on a shuttle loom or a projectile loom. The process starts with harvested yarn being spun into yarn and then dyed (most often indigo-dyed, making them the classic blue color) and then woven.

All denim is created through generally the same process:

- Cotton fibre is spun into yarn

- Warp yarn is dyed, weft is left white (usually)

- The yarns are woven on a shuttle loom or projectile loom

- The woven product is sanforized

Dyeing

Denim was originally dyed with indigo dye extracted from plants or from dried and fermented leaves (in South Asia). Most of it today is dyed with synthetic indigo dye. The yarn undergoes a repeated sequence of dipping and oxidation – the more dips, the stronger the color of the indigo. The fabric is divided into two categories: indigo dyeing and sulfur dyeing. Indigo dyeing produces the traditional blue color or shades similar to it. Sulfur dyeing produces specialty black colors and other colors, such as, red, pink, purple, grey, rust, mustard, and green.

Weaving

Most denim made today is made on shuttle less loom that produces bolts of fabric 60 inches or wider, but some is still woven on the traditional shuttle loom, which typically produces a bolt 30 inches wide.

Vintage machine shuttle looms that fell out of favor for more quicker and more efficient machines in the early-mid twentieth century is used to produce selvedge denim, which has self-finished edges. The self edge, besides for being aesthetically pleasant, prevents the fabric from fraying and unravelling and generally (but not always) is a sign of high quality.

Shuttle Loom

Projectile Loom

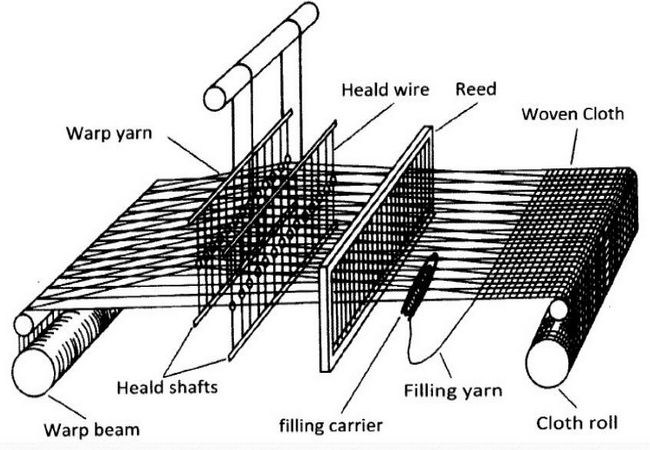

The weft thread is passed through the wrap threads in a back and forth motion, with no breaks in the weft. This creates a very smooth and sturdy selvedge edge. Put simply, wrap yarns (vertical yarns) are set in the loom, the pattern is programmed in, and a shuttle carrying the weft yarn (horizontal filler yarns) is shuttled horizontally across the loom which in then beaten together with warp yarns to begin creating the fabric. The shuttle makes numerous continuous passes back and forth with that single weft yarn which is what creates the finished edges.

A traditional shuttle loom can produce on average about 150 picks (rows of weft yarns) per minute and was the industry standard for quite some period until companies began favoring machines that could weave fabrics at much higher speeds. Amongst many that came, most common one used for denim manufacturing is the projectile loom.

The projectile loom produces non-selvedge denim as there is a single weft thread for every row and not one thread woven throughout. The projectile loom shoots the weft yarn yarns (instead of shuttle) across the wrap one row at a time that work in sequence to form the fabric. The wrap yarns are still set into the loom but instead of a shuttle, there are multiple smaller projectiles that grip onto the end of the weft yarn and shoot it across the loom through the warp yarns. This rapid fire sequence can produce well over 1000 picks per minute, and that’s on a textile that’s often twice as wide.

This process where the projectiles don’t loop back around with the weft yarn when it reaches the other side of the loom, the weft yarn is cut at the edges which creates a more delicate edge that needs to be sewn (overlock stitch) to keep from fraying.

Non-selvedge denim can differ from selvedge-denim not only because of the type of machine used but also for a combination of factors such as yarn dye process, weight of fabric, speed in which the fabric is made, etc. As mills are more focused on quantity instead of quality, they prefer using the faster projectile looms.

If you are interested in knowing more about the various types of machines, please watch the following video.

Different types of Denim

There are basically six different types.

- Indigo Denim: Indigo Denim is achieved by dying the wrap threads indigo dye and white threads are used as weft. As a result, most blue jeans are blue on the right side, as the fabric is wrap facing, and the interior is light blue, almost white.

- Stretch Denim: Stretch denim is produced by weaving spandex or another classic component to give the fabric some added flexibility. This type of denim is used for skinny jeans.

- Crushed Denim: This type of denim is created by weaving with an over twisted weft yarn, giving the denim a permanently wrinkled, crushed look.

- Acid-Wash Denim: This denim is treated with chlorine and a pumice stone to create a marbled block.

- Raw Denim: As the name suggests, the Raw denim refers to denim in its ‘Raw’ state, that it has not been treated or washed in anyway. Also, known as ‘Dry’ denim or ‘Unwashed’ denim.

- Sanforized Denim: Raw denim can shrink up to 20% on the first wash. Sanforization stretches and pre-shrinks the fabric before it is cut or washed to reduce the shrinkage to less than 3%.

Many denim articles are washed to make them softer and to reduce minimize shrinkage even beyond what Sanforization prevents. Significantly washed denim can resemble dry denim which has faded naturally over extended use. Such distressing may be supplemented by chemical treatments or physical techniques such as stone washing.

Some interesting facts about Denim

- A grand total of 225 pairs of jeans can be made from just one bale of cotton

- Each person in America owns an average of 7 pairs of jeans

- Denim Jeans weren’t known as ‘jeans’ unitl the 1950s – before this point, they were referred to more commonly as ‘overalls’.

- Around 7.5 billion feet of denim fabric is produced every single year

- May 20th is regarded as the birthday of blue jeans, since it was the day when Levi Strauss patented his idea

- Every year, around 450 million pair of jeans are sold in America

- The oldest pair of jeans to be discovered was found in 1998 down an old mine. According to the date, they were 115 years old.

- The smaller pocket in the larget pocket of your jeans was designed originally for a pocket watch.

- Yoshida Kogyo Kabushikikaisha is the company which makes 90% of the world’s zipeprs for jeans. The intials YKK can be found on the zippers.

- Denim has been around for several hundred years, but in the 1960s, people began to see it as a sign of rebellion among young people.

Conslusion

The Denim manufacturing process is a completed and detailed one. In this article, I have tried to give an overview of this popular fabric and I hope you have gained knowledge that is more than that of an average person. We at N2N Sourcing help our clients source great Denim products from Bangladesh. You can learn on how we source these products here

In the future, I am planning to write more on denim including the entire manufacturing process and some popular styles that have evolved. Till then take care!!!